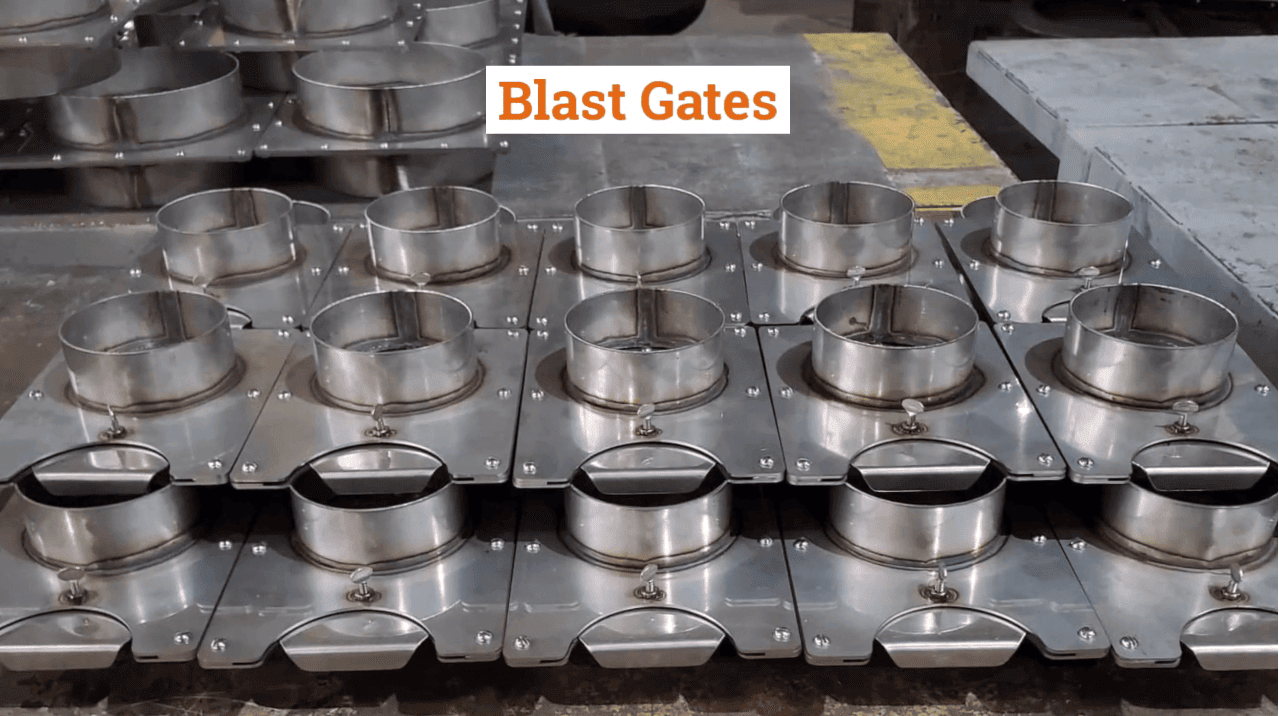

Many manufacturing processes produce a lot of dust. Whether it is a combination of wood dust, plastic, or powder in the air, a dust collection system is necessary to avoid the risk of explosion, respiratory problems, and production issues. Blast gates are simple and effective pieces of engineering designed to control airflow in dust collection and duct systems.

When sourcing blast gates, you need a manufacturer with expertise in the field. Winkler Blastgates, a division of AGI Fabricators, has been producing the highest quality spiral and oval ductwork, precision cast blast gates, and duct accessories for more than five decades. Our team can help you select the design and specifications of your custom blast gate.

Benefits of Custom Blast Gate Fabrication

For dust collection systems, custom blast gates offer unique advantages over standard or off-the-shelf blast gates. Here’s why you should consider custom blast gate fabrication:

- Greater flexibility in design and specifications

- Improved compatibility with unique systems

- Enhanced performance and efficiency

- Reduced maintenance and replacement costs

Steps in the Custom Blast Gate Fabrication Process

At Winkler Blastgates, we make the custom blast gate fabrication process simple for our customers. First, we gather customer-supplied drawings or other information about project requirements and intended application. Based on this information, we determine the material type, thickness, and grade for your custom blast gate solution. We create a drawing of the blast gate and send it to you for feedback and approval. Then we begin fabrication, followed by packaging and shipping.

Configure Your Custom Blast Gate

Or call us at (414) 438-6700 to start your custom blast gate fabrication solution.

Material Selection Options

Material selection is among the most critical decisions when producing custom-fabricated blast gates. From our experience, carbon steel, stainless steel, and aluminum are the best materials for high-quality blast gates that suit various applications, so these are the main types of materials we use.

Blast Gate Types and Specifications

Cast Half Blast Gates

These gates are designed for existing applications that require regulation or full closure of existing ductwork. They are specifically designed to be added to existing duct runs without cutting the duct apart to add a full gate. A simple slot is cut into the duct and the half frame allows the technician to fasten the gate to the duct using sheet metal screws..

Cast Full Blast Gates

Cast full blast gates are full circular gates designed to work as shutoff valves in duct systems. They are inserted into a duct run between duct joints to allow for partial or complete flow regulation in the individual duct run.

Skeleton Blast Gates

Skeleton blast gates All of our Skeleton Gates are self-cleaning, featuring a longer slide. This allows the user to quickly clear accumulated material from the blast gate opening. Skeleton Blast Gates are used for installations requiring a two-way gate control. This gate is ideal for bagging and filling operations beneath hoppers and spouts where dry materials are used.

Pneumatic Blast Gates

Pneumatic Blast Gates are commonly used in commercial and industrial duct systems, especially those involving large volumes of material or airflow. These gates are actuated using compressed air and offer greater precision and control, faster response times, easy integration into automated ducts, and lower labor costs.

Positive Seal Blast Gates

Positive seal blast gates are commonly used in applications requiring maintenance of a consistent pressure or airflow. These blast gates prevent cross-contamination and leaks between different areas of a duct system since they offer an airtight seal.

Custom Design and Engineering Considerations

Depending on your application, your blast gate will need various specifications that we can help you fine-tune. Below are the main considerations when custom designing and engineering custom-fabricated blast gates:

- Size and shape

- Material type/grade

- Actuation method

- Seal type

Other Fabrication Notes, Features, and Options

In addition to the above-mentioned considerations, other custom fabrication options include:

- Heavy-gauge construction

- Heresite-painted carbon steel for acidic conditions

- Slides and control lock in any configuration

- Standard stubs, angle rings, or pipe connections

- UHMW seals or positive seal blast gates for improved air control

- Available ID and OD sizes are shown in the product catalog. Please call for custom sizes outside our stock offerings.

- Available in any size up to 74 inches

Quality Assurance and Testing

Winkler Blastgates provides our customers with quality assurance and testing to ensure they receive nothing less than high-quality products. We perform visual inspections and test slide movement, as well as all additional customer-requested testing or inspections. As proof of our commitment to compliance with industry standards and regulations, we fabricate our blast gates to SMACNA Industrial Duct Standards. Our quality assurance team also conducts performance testing and validation.

High-Quality Custom Fabricated Blast Gates From Winkler Blastgates

Blast gates are crucial components that help control airflow in dust collection and material handling systems, which improve the health, safety, and productivity of your facility. At Winkler Blastgates, we can help you through the custom fabrication journey with everything from design to drawings to submittals to specifications. Check out our catalog or contact us today for more information. To discuss your custom solution, request a quote.