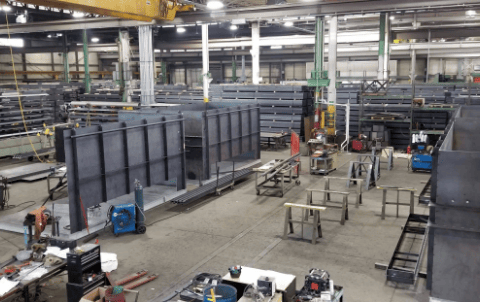

Leaders in Sheet Metal Fabrication.

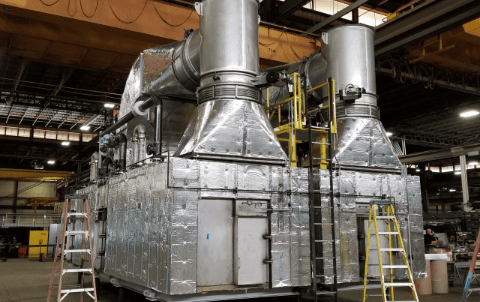

Since 1893, AGI Fabricators has been one of the most well-respected companies in the sheet metal fabrication industry. Our manufacturing team works with a multitude of different materials, grades, and markets, delivering high-quality products each and every time. Our process starts with our engineering team, who identify and shore-up any potential design bottlenecks. From there, it hits our production staff, who fabricate your product to that perfected specification. Throughout the entire process, our management and engineering staffs oversee the manufacturing process for quality assurance and that AGI satisfies all deadlines in a prudent fashion. Our work ranges from spiral duct manufacturing to custom HVAC fabrication and all the way up to large-scale industrial applications, like thermal oxidizers.