Ductwork Projects

- 72in Stainless Steel Process Inlet

When building large pollution control equipment, fabricating equally large ductwork is a typical project for our team. Fabricating and assembling over 80 feet of 72-inch stainless process inlet ductwork helped bring this project together. This portion of ductwork was first fit to the system within our facility and then pulled away to finish welding. Following a quick round of dye-penetrant leak checking and a quality control review, this ductwork was ready for shipping.

- Aluminum Marine Systems

A newer project opportunity in the shop has the team building marine grade ductwork. For this portion of the ship, aluminum ductwork was required. Utilizing a mix of MIG welding and TIG welding these pieces are awaiting their final quality check. With the application requiring corrosion resistance and weight considerations, aluminum is the material of choice for construction. Another challenge of this project relates to the tight quarters and unique obstructions that the ductwork must run around. Accuracy is critical and our team delivers.

- Polished Food Grade Exhaust

Moving away from our typical heavy industrial fabrications, a couple pieces of food-grade stainless exhaust ductwork made their way through the shop. Following our food-grade procedures and customer specifications, this piece of duct was ready for install straight from the shop floor. When the customer application requires it, pieces like this can be isolated and fabricated in our dedicated stainless steel fabrication space.

Pipe Fabrication Projects

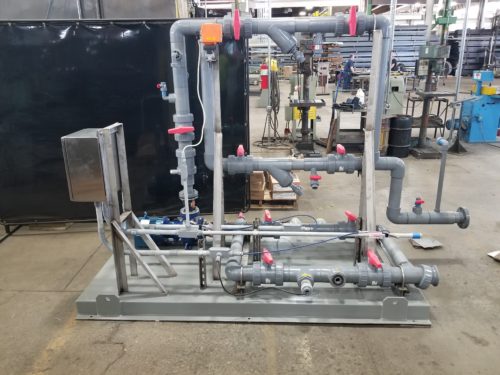

- CPVC Process Skid

Our talented pipe fitting team has skills beyond welded pipe. Building this CPVC process skid leaves no room for error; high concentration acid flows through these components so leaks and fit up are critical. Bringing the full skills of our team together allows us to incorporate electrical into our turn-key solutions.

- Fuel and Process Trains

When building ready to install equipment, the team is often tasked with combining multiple piping systems on a surface. Starting with the welded fuel train set the locations for the remaining process tubing. Working around the existing fuel train, our team was able to weave the stainless tubing and fittings to each of the ports on this fabricated equipment. Running into collision issues between components is a non-issue as our team adjusts on the fly to ensure the cleanest installations possible.

- Hot Water Boiler Piping

Carbon welded pipe is a daily task for our steamfitters. Often working with sub-par equipment flanges, we adjust our weldments on the fly. Ensuring the customer has a single point in and out to pick-up in the field is critical. Bringing all of the required project components together with welded hot water boiler piping, this skid is another satisfied customer.

- Stainless Heat Exchanger Tube

Retrofitting to existing equipment always presents unique challenges. Whether it’s taking customer dimensions or our field team’s drawings, creating plug-and-play fabrications is our specialty. This stainless steel burner tube successfully replaced a failed component in a customer’s system. Welded to process piping specifications this piece was built and installed without any issue.

Equipment Projects

- Air to Water Heat Exchanger Skid

Working through our fifth and sixth iterations of this project, the customer has continuously grown the needs for this system. Starting with large stainless duct plenums to connect two air to water heat exchangers, we finish these skids with a Hastelloy-C276 exhaust spool. Building each component from the ground up and bringing them all together for a complete system assembly is a refined skill of our team. Each heat exchanger is then connected on the water side with interconnecting B31.3 process water piping. The finishing touch on this system is a seismic-rated platform for each skid before testing and shipping breakdown. - 3-Can Thermal Oxidizer

Bigger IS better when it comes to helping our customer’s engineering teams dream up the best possible solutions for a project. Utilizing our 25’ of crane height, the team was able to fully assemble the various components of this 3-Can Thermal Oxidizer. With most of the larger fabrications, there is a need to incorporate structural platforms, ductwork, fuel piping, process piping, and full-system fit up. Being able to bring these numerous components together in our shop before delivery to a customer site is critical to minimizing installation time on site and getting the end-user operational as quickly as possible. - Boiler and Pump Skids

Boiler skids, pump skids, and utility skids are becoming a very desirable equipment option. Single point inlets and outlets allow these boiler and pump skids to drop into a customer’s existing mechanical room. Accuracy is key to ensuring these systems meet the project specifications of a plug-and-play solution. Additionally, having certified structural welders and certified pipe welders allows us to complete these projects efficiently as they move across our shop floor. A finishing touch for the turn-key system is a day or two in our paint area to complete the project.

Structural Projects

- Engineered Tank Support Structure

Utilizing our engineering resources, we were able to maximize the usage of our top-end 28’ of crane height to design and build this carbon-steel structure. Our D1.1 certified welders used flux-cored wire to fully weld each of the connections, minimized the need for field fit-up and assembly. Being able to fully assembly a structure at this height allowed further modifications throughout the project such as added bracing to ensure structural rigidity & minimizing sway in the structure.

- Cooling Tower Maintenance Access

Working on the roof of your building can complicate a project. Working on the roof of your building and servicing large equipment from ladders makes this even harder. This custom solution created an engineered access platform around a customer’s cooling towers to allow greater maintenance access and a much-appreciated level of safety during cleaning. With structural engineers on staff, 3D modeling capabilities, state-of-the-art fabrication facility, and our certified welders, this custom carbon steel platform was built and assembled to ensure a seamless install.

- Stainless Mounting Platform

When mounting process equipment, many facilities are moving to pre-fabricated skids. This project required various support members across the stainless steel framing of this skid. Our D1.6 certified welders were able to use stainless flux-cored wire to meet the customer guidelines and ensure elevations, squareness, and aligned mounting holes were maintained throughout the build. This project went out for glass-bead blasting as a finishing procedure; it didn’t have to move far because we blast in our outdoor space on-site as well.